Step into the heart of a manufacturing facility where innovation meets craftsmanship.Read More

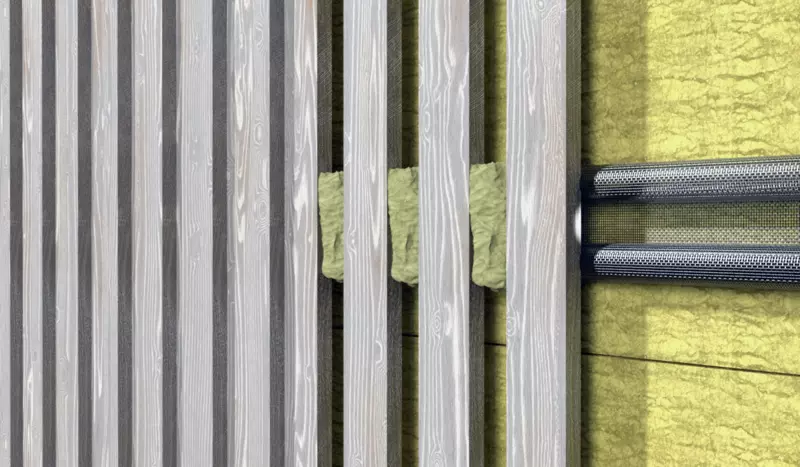

This article takes you behind the scenes of this dynamic environment to understand how precision engineering and streamlined production processes come together to meet modern demand. Cut and edge panels are pre-sized, laminated wood-based panels with precisely finished edges. They are the building blocks of modular furniture, bespoke cabinetry, and large-scale interior fit-outs. Their uniformity, finish quality, and dimensional accuracy save time for carpenters and interior designers, offering a plug-and-play solution in fast-paced projects. Factories that specialise in this type of production must meet high expectations: speed, scale, and flawless finish. From sourcing the raw materials to packaging the final panels, each stage is carefully calibrated. One of the standout features of a modern factory is its investment in cutting-edge machinery. Beam saws, CNC routers, and vertical panel saws allow manufacturers to cut multiple boards in one go, ensuring accuracy down to a fraction of a millimetre. CAD software guides the process, transforming design files into precise instructions for machines. This eliminates human error and significantly boosts productivity. In large factories, automation allows one operator to oversee multiple cutting lines at once, greatly reducing turnaround time. Once panels are cut, they move to the edging line. This stage involves bonding edge bands—usually made of ABS or PVC—to the raw sides of the board. Edge banding not only improves aesthetics but also protects against moisture, impact, and wear. Hot melt adhesives and PUR glues are used depending on the durability requirements. Edgebanders in today’s factories include pre-milling, corner rounding, and trimming units to give a smooth, seamless edge. Quality checks at this stage ensure there are no glue lines, gaps, or visible joins. Factories handle a wide range of board materials—from MFC (melamine-faced chipboard) and MDF to plywood and HPL (high-pressure laminate). A key trend is the increasing demand for customisation. Clients now seek unique textures, colours, and finishes that reflect current design trends. To meet this, manufacturers keep a versatile stock of decorative panels and offer matching edge band options. Some even allow digital printing or laser edging for ultra-premium jobs. This flexibility keeps the factory competitive in a market that values personalisation as much as performance. Efficient workflow is essential to keep up with large-volume orders. Conveyor systems, barcode tracking, and ERP software help in managing the entire process from order to dispatch. Every panel is logged, tracked, and optimised through nesting algorithms to minimise waste. These digital systems also allow clients to submit designs remotely, track their job status, and schedule deliveries. It’s a far cry from traditional woodworking shops—today’s cut and edge panel factories operate more like tech-driven production hubs. While machines do most of the heavy lifting, skilled technicians play a crucial role in programming machines, conducting inspections, and troubleshooting. Quality control is embedded at every stage, with inspections for edge bonding, panel dimensions, and surface finish. Final products must meet strict tolerances. A minor deviation can delay an entire installation project. That’s why trained staff are indispensable in maintaining consistency and handling bespoke or irregular jobs. A visit inside a Cut and Edge Panel Factory reveals a blend of engineering precision, digital efficiency, and human oversight. These facilities are the backbone of the modern furniture supply chain, delivering components that are ready to assemble, install, and admire. As demand for faster, high-quality interiors grows, these factories are evolving into smarter, more responsive operations—where every cut counts and every edge matters.The Role of Cut and Edge Panels in Manufacturing

Precision Cutting Technology

Edging for Durability and Finish

Materials and Customisation

Automation and Workflow Optimisation

Skilled Operators and Quality Control

Final Thoughts